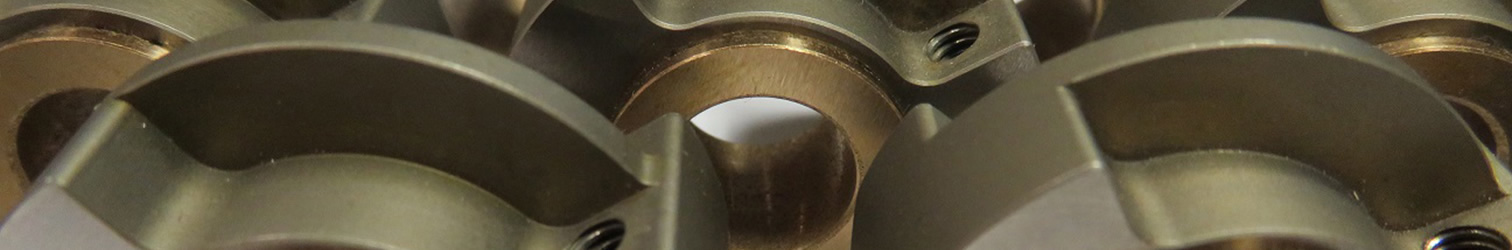

SERVICES - Leader in Precision Machining

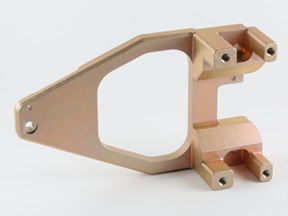

At Dexter Design, we take a collaborative approach to the manufacturing process to ensure the end-product meets the exact specifications for form, fit and function. This is achieved through multiple quality control inspection points, as well as applying years of knowledge and machining expertise by a team of highly skilled CNC machining specialists.

We are on the cutting edge of innovation and are continually refining our capabilities with the latest state-of-the-art equipment and technology. Our employees undergo rigorous ongoing training to stay abreast of industry advancements, and we continue to push the envelope for maximum efficiencies and performance.

We are a full service CNC machining facility, we utilize a broad range of materials:

- Titanium

- Plastics

- Stainless steel (300 ,400, 17-4, 15-5 )

- Steel

- Tool steel

- Tungsten

- Invar

- Aluminum

- Brass

- Copper

- Bronze

Please review our Terms & Conditions.

QUALITY CONTROL – Every Detail Matters

CNC Machining requires absolute precision. At Dexter, we take this to heart and approach every job understanding there are no margins for error. Every detail matters at each step from original concept through final production. What others may see as cumbersome, we embrace as a necessary process to perfection.

To ensure quality control, we have well-established protocols for conducting measurements and tests that follow the National Institute of Standards and Technology (NIST) guidelines. We guarantee objective, verifiable evidence at the multiple inspection points of any given project.

We are always seeking ways to be more efficient and yield even tighter precision. The process of improvement is ongoing, and Dexter Design is committed to staying on the cutting edge. Our QC department is fully equipped with state of the art capabilities; we also have the ability to supply First Article Inspection's PER AS9102.

CAPABILITIES – Absolute Precision

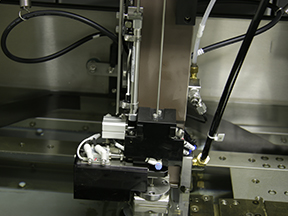

Dexter Design has engaged in increased capacity and various technology innovations to stay ahead of the competition and accommodate client requirements. Dexter Design has implemented Shop Tech's E2 RP system which has enabled us to streamline the work flow process for efficiency and cost savings to our customers.

2019 Equipment Acquisition

4-Axis linear motor driven wire EDM capable of machining to very tight tolerances and creating a superior surface finish on parts with intricate geometry.

CLIENT SATISFACTION – Unparalleled Customer Loyalty

Dexter Design has built a solid reputation for being a quality machine shop with a 99% customer satisfaction rate for visual, dimensional and performance quality, as well as consistent, on-time delivery. Our customer loyalty spans decades and we still serve customers who have relied on Dexter Design from the first day of operation in 1984. This is why we say, “Family runs deep at Dexter.”